|

| Clean and ready to go. |

|

| The oil separator went in first. I used blue Loktite on the screws because some of them were really short and the last thing I want is one of them vibrating loose. |

|

| The kickstart assembly went in next and that was it for the bottom half. |

|

| My little makeshift engine stand has really come in handy lately. |

|

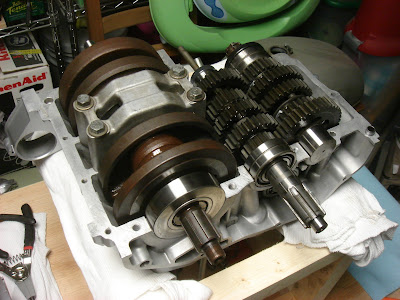

| Gearshift forks went in first. |

|

| And then the camshaft. |

|

| All of the oil seals have been replaced with OEM seals from BikeBandit.com |

|

| The transmission with new oil seals in place. |

|

| Don't worry, I didn't forget the cam chain. The next step will be to seal the upper and lower halves together and crack on with the rest of the assembly. |